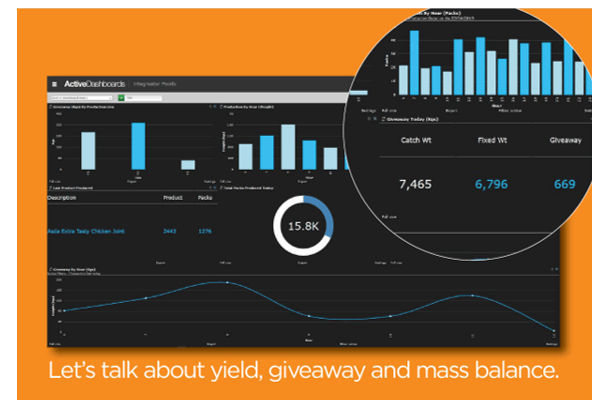

Yield and Giveaway Management Software

Need to reduce giveaway on fixed weight products, improve yield and achieve better scheduling?

Increases in yield, decreases in giveaway and an industry-leading mass balance; these are the things that make every food manufacturer more profitable. Whenever there are losses attributed to poor yield or excessive giveaway, even the smallest of changes can have a dramatic impact on better margins.

And for manufacturers dealing with fixed weigh products, if they can minimise giveaway then the results can be game-changing.

70% of UK food manufacturers adopting “overfill” to ensure compliance with legislation; the inevitable result always hits the bottom line.

Accurate measurement of product yield is critical for any food processing business to optimise raw material, reduce waste and maximise profit margins.

Tight profit margins mean that even a slight miscalculation can lead to a loss, with large production runs often magnifying the problem.

To download your copy of our new interactive guide click here:

SI’s Giveaway Tracker tool monitors giveaway both during and at the end of production, and against the actual weight products for fixed-weight products. It analyses not just the weight differential, but also the associated value. It also:

- Measures yield for your entire product range, accounting for all variants and complexities.

- Allows yield specifications to be set for each and every product.

- Measures performance by comparing actual results against these criteria, and immediately alerting operators to any discrepancies.

- Identifies where profit and loss are being made, by either individual or grouped items.

For example, in the case of a 10kg fixed weight product, Giveaway Tracker will:

- Pick up and store both the actual and fixed weights, as the product travels across the scale.

- Record weights by individual item and provide a visual to show weight giveaways by product and aggregated by run number.

- Show the associated cost incurred of product giveaway.

Any inefficiencies can be immediately targeted, including any individual errors that may have occurred whilst issuing and returning raw materials to different groups and areas.