Customers

Bearfields of London streamlines production with digital transformation from SI

SI’s digital transformation project has delivered extraordinary results for Bearfields of London. “If I was to summarise the biggest benefits we’ve realised since the implementation, it’s been all about transparency, streamlining operations, working leaner and smarter. And 100% transparency means that we have far less cash tied up in stock.” Steve Bearfield, managing director, Bearfields of London

-

Aquascot

From Catch to Despatch: Aquascot selects SI for Digital transformation partnership

“With SI as our digital transformation partner, Aquascot will be more resilient and be able to optimise our production efficiencies.”

-

Farmison & Co

Award-winning catering butcher partners with SI to streamline processes through full integration of its operations.

"SI has an outstanding reputation for delivering software within the meat industry and an in-depth understanding of the pressure points faced by catering butchers," Liam Duggan, Finance Manager, Farmison.

-

Fairfax Meadow

Fairfax Meadow, the UK’s leading catering butcher, processes more than 3,000 orders daily. SI's strategic integration project will deliver a real-time view across its entire multi-site operation.

"SI's tacit knowledge of the meat industry is really useful. They understand multi-site operations and our unique business challenges," Tony Carlisle, Head of IT & Systems, Fairfax Meadow. -

Regal Food Products

"When we evaluated ERP providers, SI's people, industry knowledge and software stood out." Absar Younis, Operations Director, Regal Food Products.

A real-time view of stock, improved throughput, efficiencies and total process visibility; for Regal Food Products, SI's solution met all of their challenges.

-

Finnebrogue Artisan

Since 2014, SI's integrated data approach has been supporting Finnebrogue's new Downpatrick processing plant success.

"The reason we chose to work with SI was that the team was both flexible and aligned to our culture of getting things done." Finnebrogue Artisan.

-

Falfish

For over 6 years, Cornwall-based Falfish has made the most of SI's ERP software including intake and cold store stock control, SFDC, QA, traceability, and a bespoke trawler catch payments module.

"SI's software allows us to fulfil customer demands to the highest standards, whilst maintaining fully automated and auditable traceability." Mark Greet, MD, Falfish.

-

Avara Foods

After investing in its 100,000sq.ft Telford factory, Avara Foods (previous known as Faccenda Foods) took the opportunity to look for a new production management system. "We needed a pure software solution that could be used right across our estate.

"We needed a system to grow with us. SI's Integreater could do that." Philip Davidson, Operations Director, Faccenda Foods.

-

Baird Foods Services

When Bairds needed turn a warehouse into a fully integrated outsourced meat processing factory in 12 weeks, the company turned to SI to deliver its vision for a technology-driven service operation.

“SI was a great cultural fit from day 1, as they understood both the industry terminology and the cuts of meat to be processed. In fact, they scoped out the solution in just one week." Kevin Horner, GM, Baird Foods Services.

-

Pickstock

"Our complex requirements meant that SI's specialist abattoir management software was the obvious choice." Hayley Draper, Lairage Manager, Pickstock.

Processing 2.5K animals each week, the speed at which SI's livestock management system identifies, grades, labels and allocates each animal means that Pickstock can ramp up production whenever customer demand increases.

-

JCS Fish

JCS Fish and SI have been working together for several years. This family-run firm has made the most of our integrated technology to support its business expansion and customer demands.

“SI's food ERP allows us to have complete control over our whole food process, traceability, food hygiene and food quality. I think SI is a fantastic business to be partnered with." Jack Coulbeck, Commercial Manager, JCS Fish.

-

South Caernarfon Creameries

Multi-award winning South Caernarfon Creameries' (SCC) produces cheese & dairy products for the UK’s leading supermarkets. Seven years ago, the Welsh co-operative invested in SI's Integreater to support its business growth ambitions.

“SI’s flexible and modular software offered more functionality than standard MES and has been developed by food processing experts." Robert Burgess, Finance Director, SCC

-

Vantage Foods

For over 12 years Vantage Foods & Systems Integration have worked closely together at each of Vantage’s four meat processing plants in the USA & Canada.

“Creating my daily plan is so easy with SI. Integreater automatically calculates everything we need to achieve 100% order fulfilment, while using raw materials and labour in the most efficient way." Kerry Castillo, Scheduler, Vantage Foods.

-

R&G Fresh Herbs

Following a multi-million-pound investment in its Farnborough processing facility, R&G Fresh Herbs selected SI as its MES provider to digitally control its entire herb preparation and packing processes.

“What's been really eye-opening is the real-time view we now have across the entire business. Benchmarks & KPIs can be precisely reported on at any time of the day." R&G Fresh Herbs.

-

DB Foods

“SI and Integreater was the outstanding candidate when we looked at the marketplace." Gary Smith, Finance Director, DB Foods.

“When we started our search for a software solution, the challenge we faced was that nothing seemed to be tailored for our industry. With SI, we immediately realised that we didn’t have to develop our own product or spend heavily on integration."

-

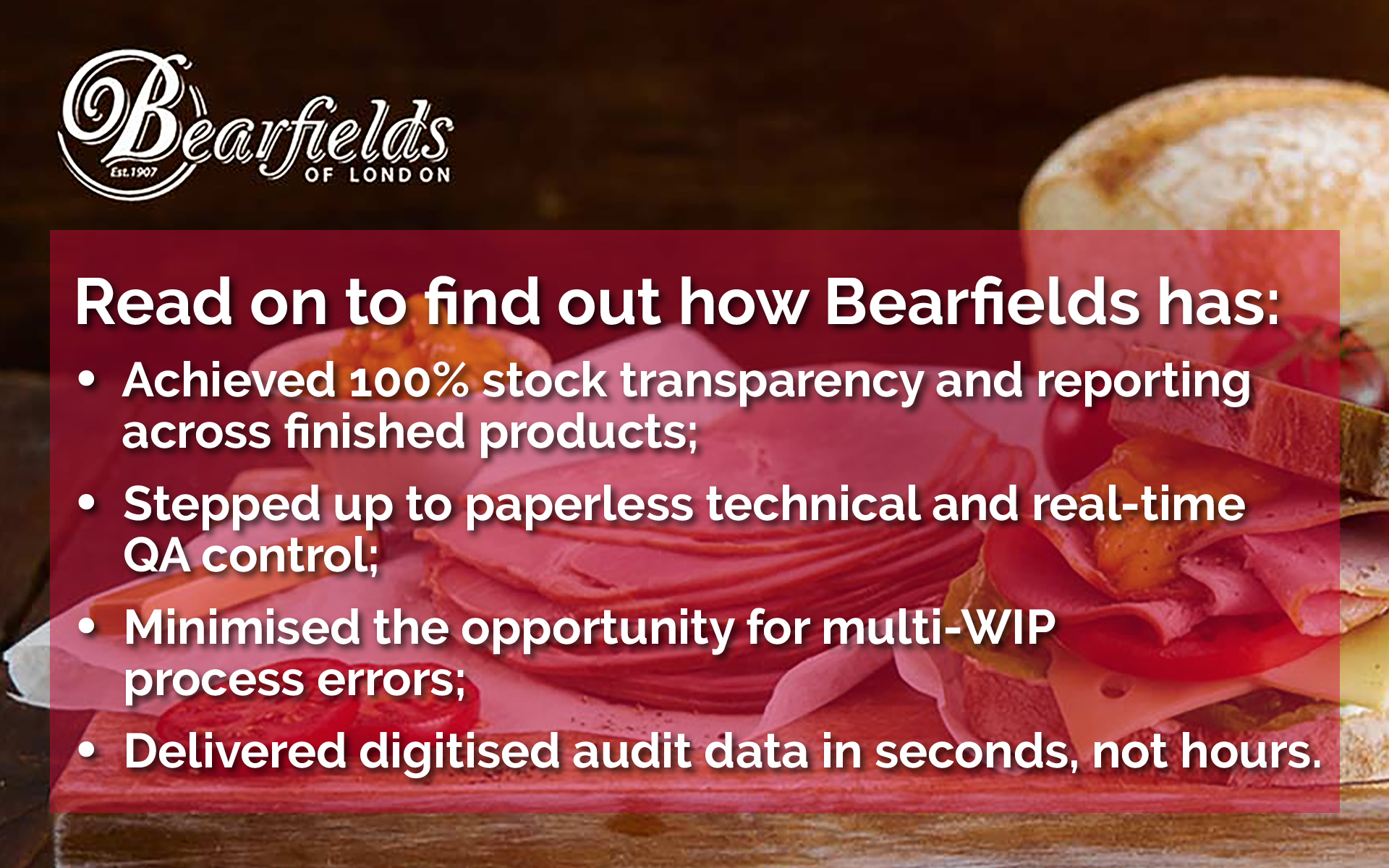

Bearfields of London

Bearfields of London processes and delivers over 20,000 pork legs every week, throughout the UK. Some of the biggest names in the catering industry rely on Bearfields to supply them with the highest quality products.

SI has been working with the Bearfields for the past four years. During this time, we’ve installed our modular shop-floor data capture software and ERP across Bearfields’ end-to-end, multi-stage and complicated production processes.

-

Fresco Fisheries

Fresco Fisheries partner with SI to compliment growth strategy through digital transformation

“By Partnering with SI, we are embarking upon a digital journey to future proof our business. We have taken the decision to implement in phases and take advantage of SI’s modular software to mitigate risk and ensure we continue to meet (and exceed) customer expectations delivering on-time in full,”

-

Harmony Beef

When Alberta-based Harmony Beef explored the market to find a solution to manage its entire production process, SI shone out as the obvious choice.

“SI's market knowledge is extraordinary. I've owned meat businesses for over 40 years I've always struggled to find a software provider with this level of knowledge. No other food ERP system can meet our needs the way Integreater can.” Rich Vesta, CEO, Harmony Beef.

-

Hilton Seafood Group UK

"I would recommend SI to other food processing businesses. Its touchscreen OCMs are so easy to use; they increase productivity, and it took less than 10 minutes to train our operatives." Steve Wallace, IT Manager, Hilton Seafood Group UK.

Hilton Seafood (previously known as Seachill) is one of the UK’s leading fresh fish processors and the owner of the Saucy Fish Co.

-

Campbells Prime Meat

When Campbells Prime Meat decided to invest in food processing software,, it was SI’s expertise within the food service sector stood out for this award-winning business. “We spoke to several generic IT software suppliers who failed to understand our processes.

“When we met Rob Stephens, SI's CEO, it was different. He truly understands meat processing & that was the connection point. What Rob says carries a lot of weight because he’s done our job.” Steven Sweeney, FD, Campbells Prime Meat.

-

AK Stoddart

AK Stoddart is one of Scotland's leading beef processors. Renowned for its for exacting standards and all-round excellence, its aim is quite simple: to continuously improve productivity, quality, customer service and provide the ‘best in beef’ – year in, year out.

“With SI’s software in place, we're assured that 100% of MHS health information is accurately gathered and attributed to the correct animal and batch." John Craig, Operations Director, AK Stoddart.

-

Butlers Farmhouse Cheeses

For more than 70 years, Butlers Farmhouse Cheeses has been dedicated to making the very best handmade farmhouse cheeses at its Cheshire dairy & Lancashire farm. SI has been delivering production improvements and on-demand reporting for this award-winning cheesemaker.

"Within a short leadtime, SI's Integreater delivered greater control and visibility of our production processes right across the business." Justin Burton, Financial Controller, Butlers Farmhouse Cheeses

-

Millers of Speyside

Moving away from an embedded IT system is a critical decision of any food processing business, but when Millers of Speyside decided to move up to a specialist abattoir management software solution, it chose Integreater.

-

Denholm Seafoods

From boat to port, through processing and onward delivery, Denholm Seafoods is focused on consistently ensuring high-quality pelagic fish for its customers, whilst ensuring full traceability. SI has been working with Denholm since 2015.