Falfish Information

Seafood processor Falfish takes digital integration to the next level with SI

Leading multi-species seafood processor, Falfish is one of the first businesses in its sector embracing the benefits of digitally-led process control. By removing manual processes, Falfish is supporting greater integration with both suppliers and customers.

For more than five years, this independently-owned business has been investing in state-of-the-art processing facilities, dramatically changing the way it works. Throughout this time, SI has collaborated with Falfish by developing and customising specific software, to support the ways that the company does business.

Mark Greet, MD at Falfish said “We didn’t want to invest in a bespoke solution that couldn’t move with the times.

“SI’s food software is structured in a modular way, allowing the business to implement modules in a systematic and progressive plan.”

“As SI’s food software is structured in a modular way, we were able to implement modules in a systematic and progressive plan,” explained Managing Director, Mark Greet. “And, as customisations are built into SI’s standard software, it means that they are always incorporated into later module releases.

This software modularity proved to be a decisive factor within our overall evaluation process, we didn’t want to invest in a bespoke solution that couldn’t move with the times.”

Putting fishermen first

A major contributor to Falfish’s success is the way it works with its fishing partners. In addition to buying its fish from auctions, Falfish also guarantees to buy whole catches from skippers’ individual boats.

As Mark explained. “We have strong long-term relationships with skippers, crews and fishing vessel operators and strive to ensure we help them any way we can. As a major part of its commitment to the Cornish fishing industry, we invested with SI so our processing and payment systems are streamlined.

“This way, the skippers can concentrate on landing their catch each day, whilst maximising the value achieved from every sailing.” Find out more about SI’s Trawler Catch Payments

Mark continued. “By processing catches on the same day as purchase, we’re able to send our products straight to customers, whether it’s fresh or immediately processed for frozen customers. And, as the amount and type of seafood caught each day varies, we also need to operate with great flexibility, to ensure all orders from key customers in the UK and Europe are quickly and efficiently fulfilled.

Managing stock and orders

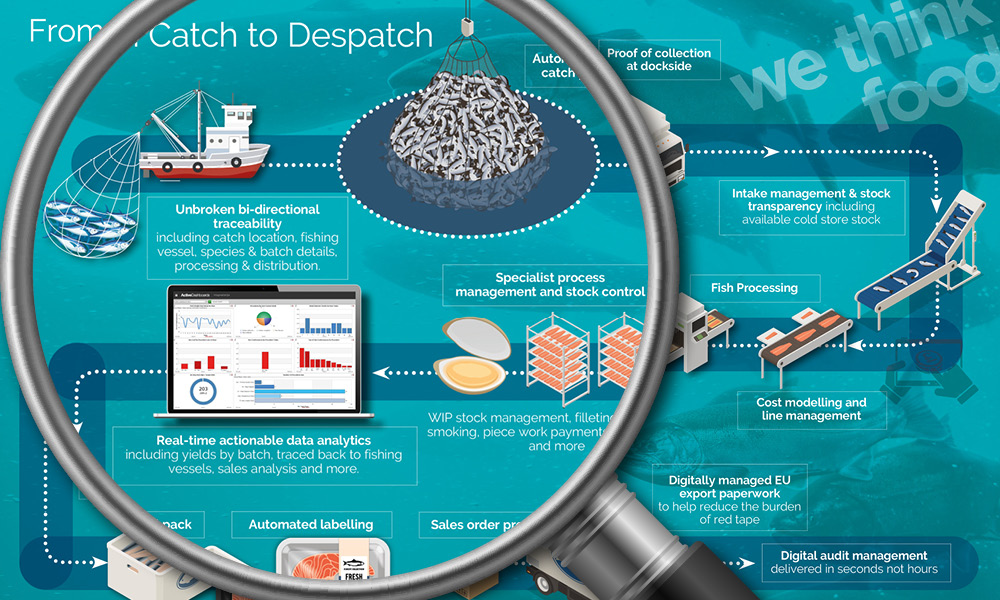

At Falfish, once the daily catches are sorted into different species and booked into stock, SI’s Sales Order Processing software matches orders to the fresh stock intake and available cold store stock. As a result, Falfish has a very quick and accurate view of stock and real-time information, enabling accurate decision making.

Tackling traceability and digitalising QA

By choosing SI’s technology for full traceability control, Falfish also has end-to-end digital tracking, enabling it to automatically report back to fisheries departments. SI’s technicians worked with Falfish, customising its chosen software modules to meet these unique industry challenges and processes, and achieve end-to-end traceability.

Talking about how the business has been able to change the way it manages traceability, using an integrated approach. Mark added: “Falfish has been using the SI’s Stock and Order modular software for some time. By adopting a batch barcode approach to traceability, where each batch is assigned unique codes, the batch code data captures all the relevant traceability details.

This traceability data follows the product throughout the processing line, together with the individual species barcode information. It informs label generation details, whenever the produce is packed and despatched, or when stock is put into cold storage. As a result, not only does SI’s software deliver a fully automated and auditable traceability system, but it also provides complete mass balance on all products and packaging.”

More recently, SI has digitalised Falfish’s QA processes, incorporating some very specific goal setting, such as using handheld devices to perform and log all QA tasks and deliver live data straight to our technical managers.

“As a result, not only does SI’s software deliver a fully automated and auditable traceability system, but it also provides complete mass balance on all products and packaging.”

Mark Greet, Falfish