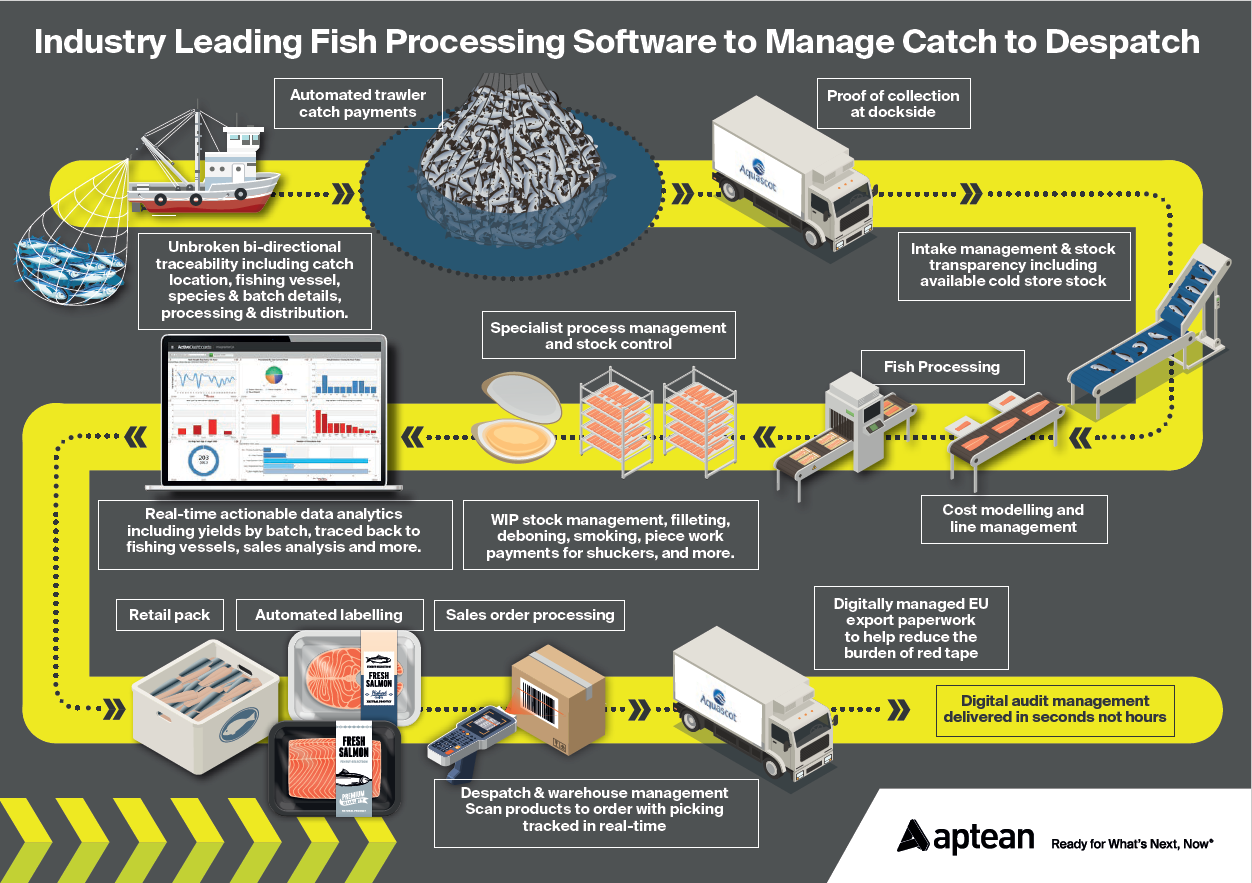

Fish Processing Software

With Systems Integration, once shipments reach the fish processing factory, we’ve found a way to simply the intake process:

Fish shipments are booked against supplier weights and labelled using our OCMs (outer case markers);

For retail pack fish, whenever the raw product needs to be issued, it’s booked against a production run at the OCM. Product can only be booked to output if it is correct.

Using our OCMs, the total intake weight is booked as the fish is sorted;

As the fish is issued for preparation, when it’s de-headed, gutted and filleted, our software captures the frame and trim weight in real-time. (Other processes may include skinning, pin-boning, square cuts);

Mixed fillet trays (or kit) are then booked as work in progress (WIP) and actual fillet weights are captured (rather than the supplier weight);

The filleted products are issued to a production line. Products can only be booked to output if it is correct.

Details are uploaded to the purchase order, according to the filleted product.

At the end of processing, when it is finished as a retail pack product, the end of line OCM will produce the final product label.

Real-time insights from batch issue to retail pack

Our OCMs manage more than just labels. They’re also managing the calculations, based on the yield, ensuring that batches are correctly changed. Whether you need to track by delivery or relatively small batches, OCMs monitor batches, preventing automatic overbooking and booking against incorrect production runs.

If a better yield has been achieved, a manual override can be made and recorded. With these checks and balances in place, booking to

production will always be done right the first time, for auditing, traceability data will be robust and accurate.

If operators attempt to book more than the expected yield, this can only be achieved by a manual override of the system. These built-in checks are designed to ensure:

- Production plans are followed.

- Operators change batches at the right time.

- Next batches aren’t accidentally booked to the run.

Read our latest article on how digitalisation of EU-export paperwork is helping to reduce the burden of red tape for one of SI’s innovative fish processing customers.

Controlling production of specialist processes

For specialist processes, such as smoked salmon, the trays of fillets are issued to the smoking process. Afterwards, the fillets are weighed and booked as a smoked product. Again, our cost modelling features a different yield for these smoked products due to weight reduction. Click here to find out more about our unique cost modelling and yield management for fish and seafood processors.

At this point, our software is keeping track of the balance for what’s been issued (using a trace ID) and the resulting weight after production, and after it’s been packed and sealed. If the weight exceeds the expected amount then production is halted.