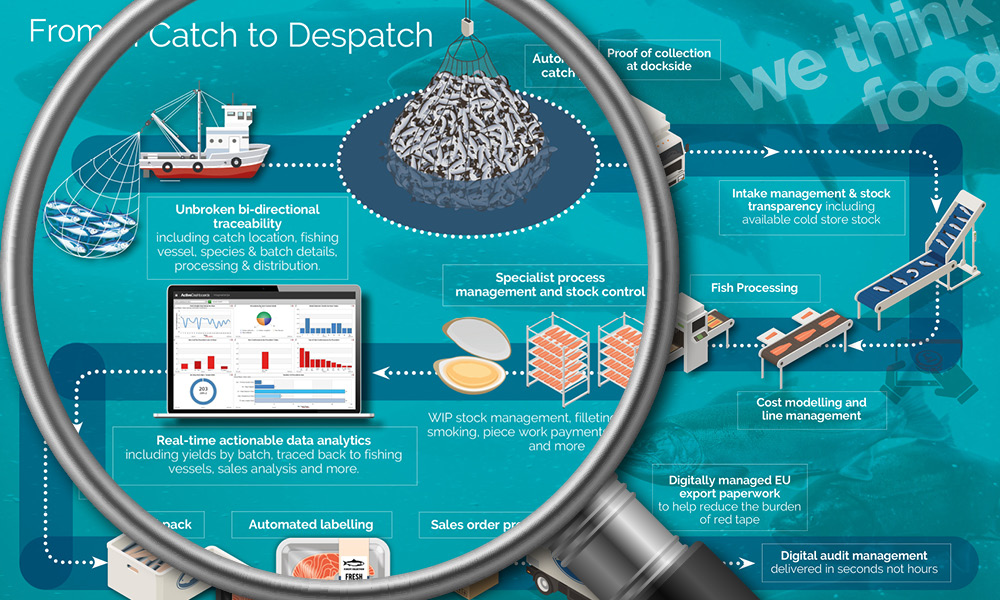

Fish Retail Packing Software

From batch issue to retail pack

With SI, whenever a batch of fish is issued for retail pack processing, it’s booked against a production run that matches the planned products with a unique batch code. The batch code data:

- includes vessel identification, the catch date, and fish quota details.

- accompanies produces throughout processing, together with individual species barcode information.

- and informs label generation, whenever the product is packed and dispatched or put into cold storage.

Monitoring yield and tracking the batch

Our Outer Case Markers (OCM and labelling) manage more than just labels and booking to the production run. They also manage the calculations, based on the yield, and ensure that batches are correctly changed.

Whether you need to track by delivery or relatively small batches, OCMs monitor every batch to:

- prevent automatic overbooking or booking against incorrect production runs;

- ensure product output is booked only if it is correct.

Fish processors can also book trays of mixed fillets as work in progress (WIP), capturing the actual fillet weights rather than the supplier weight.

Note: In the case of a better yield being achieved, a manual override can be made and recorded.

Read our latest article on how digitalisation of EU-export paperwork is helping to reduce the burden of red tape for one of SI’s innovative fish processing customers.