Integreater Food ERP

Looking for the best Food ERP system? SI has been dedicated to developing solutions for the food manufacturing sector for almost three decades, our approach has always been different. Through the combination of our modular food ERP and real-time planning software applications, driven by our renowned, fully-integrated shop floor data capture, our transformative solutions are built to fit the food manufacturing industry.

The one size-fits-all ERP solution hasn’t ever been the panacea to resolving complex food manufacturing process improvements and gaps. Invariably, this approach leads to a plethora of work-around solutions.

And with SI, we add our expert knowledge of food production and reporting to give you data driven insights, that are proven to deliver performance improvements across business operations.

The result? “One version of the truth” from every interaction, every process, every ingredient and operation, delivering digital operational control from supply chain right through to the customer. Looking for the best food ERP? SI will enable your food manufacturing business to be more collaborative, efficient, profitable and responsive.

Click on the panels below to explore our range of food ERP applications.

-

Production Scheduling

Using your finished goods forecast and sales orders, plan and schedule the more efficient way to make products, assign production lines, crewing levels, use raw materials and packaging, manage multi-stage processes and more.

-

Advanced reporting and analysis

SI’s range of SQL dynamic reports delivers advanced reporting on demand. Configure our powerful reporting and analysis tools to highlight opportunities for business improvements and investments, and monitor food manufacturing issues, such as frequent line downtime or poor throughput.

-

Price Maintenance

Store complex pricing by stock code, standard and promotional pricing and for each and every customer, offset weeks, rebates and much more.

-

Raw Material Intake Software

Manage raw material intake your way, with SI's Purchase Order Intake screen. Validate goods received and update purchase orders in real-time; create batch codes, capture weights, tares and all food industry measurements; ensure completion of all mandatory QA and traceability information; produce labels and assign to stock, and more.

-

OCM, weighing and labelling

Validate and label finished goods, maintain batch number traceability, and create stock. With accurate and verified content for labels, options include: branded label design, barcode labels, on-demand & online labels, variable labelling for catch & fixed-weight products, pallet and case labelling.

-

Materials requirements planning (MRP)

Having the right stock available at all times is vital to the success of any food producer. Too much can lead to downgrades and waste, too little to shorting orders and unhappy customers. With SI's Stock and Order MRP software, take a lean manufacturing approach to food production stock management, with a real-time view to manage raw materials, WIP, packaging, and more.

-

Shop-floor Data Capture and MES

Transform your food manufacturing processes with MES that eliminates inefficiencies, improves productivity and drives real-time decision making for continuous improvement.

-

EDI Processing

Expedite customer sales orders with SI's EDI processing. By using EDI or web portals, empower your customers to directly place and self-validate orders. Make the most of our pre-priced product order templates, that are proven to eliminate errors that often occur when sales orders are placed.

-

Stock control and warehouse management

Transform your warehouse management with an instant view of on-hand stock, available stock and shelf life status, across multiple sites.

-

Bill of Materials

Within SI's Cost Modelling module, Bill of Materials maps out all product relationships for both food manufacturing reduction specifications and combination specifications. Bill of Materials details raw material conversions to work in progress (WIP) and finished goods products.

-

Production Management

Build your daily plan in minutes, based on sales forecasts and known patterns; control multi-stage processes; measure operational efficiencies and uncover the best use of labour and raw materials to drive more profitable margins.

-

Sales Forecasting

To deliver optimum sales forecasts, a food manufacturer needs to have an overview of all business management processes and access to accurate data to enable informed decisions, including sales predictions over time, and variables, such as seasonality & grade of the product.

-

Active Dashboards

SI's Active Dashboards have the power to interpret real-time KPI data from across the food factory in a graphical and engaging way, that will benefit every operational area. This knowledge-led approach and our food manufacturing dashboards, shine a light on all areas of the business to drive informed and positive decision making, and continuous process improvements within the food factory.

-

Purchase Order Processing

Efficiently create new purchase orders for raw materials, dry goods ingredients, packaging, services, non-stock items and consumables. Choose delivery timeslots, units of measure, and colour code based on delivery status.

-

Sales Order Processing Software

Our highly configurable Sales Order Processing software has been developed to meet the operational requirements of any food manufacturing business. Features include customer templates, shopping baskets, historical sales by customer, promotions, multiple price lists, 3-tier pricing, draft orders, full audit trail, credit limits, CRM, rebates, reporting on demand, and much more

-

Production Planning

SI's food production planning provides a real-time view of scheduling, dynamic planning and allows you to make last minute changes, no matter when they happen during the day. Identify live issues and calculate the knock-on effects to production time and lines, raw materials, crew, packaging requirements and even vehicle departure times.

-

Cost Modelling

What margin will I make today? How much does it really cost to make my products? Our Cost Modelling software has the power to solve many of today's food manufacturing planning challenges. Automate calculations to achieve continuous and accurate data to help prevent overspend and unearth savings, wherever they can be made.

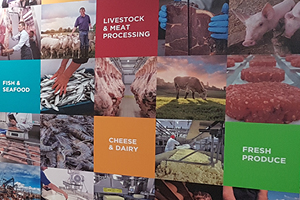

Or alternatively, choose from our sector specific software

- Sector Specific Software

- Abattoir Software Categories

- Bakery & Cake Manufacturing Software

- Catering Butchers & Food Service Software

- Cheese & Dairy Management Software

- Fish & Seafood Software

- Fresh Produce Software

- Meat Processing Software

- Pet Food & Bird Seed Manufacturing Software

- Recipe and ingredients

- Snacks Manufacturing Software

- Software for Poultry Processing