Our Software.

-

Pick, pack and despatch

At SI (Systems Integration), we’ve worked hard to find ways to overcome the daily challenges of high product proliferation, faced by wholesale butchers. Our pick, pack and despatch software is a great example of why SI is now the UK's leading provider of software to the catering butcher sector of the food manufacturing industry.

-

Pick, pack and despatch software

Managing high product proliferation picking and despatch

At SI (Systems Integration), we’ve worked hard to find ways to overcome the daily challenges, faced by wholesale butchers. Our pick, pack and despatch software is a great example of why SI is now the UK's leading provider of software to the catering butcher sector of the food manufacturing industry.

Our easy-to-use order collation application is ideal for picking within a high product proliferation environment, and ensures what’s delivered is correct and matches your sales orders.

Despatch Tracker from SI cuts credits by removing human error and ensuring what’s ordered is delivered.

DOWNLOAD our Catering Butchers Infographic here [si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]If your catering butcher business would like to discover how to improve pick, pack and despatch operations, simply complete the form and we’ll get right back to you.

-

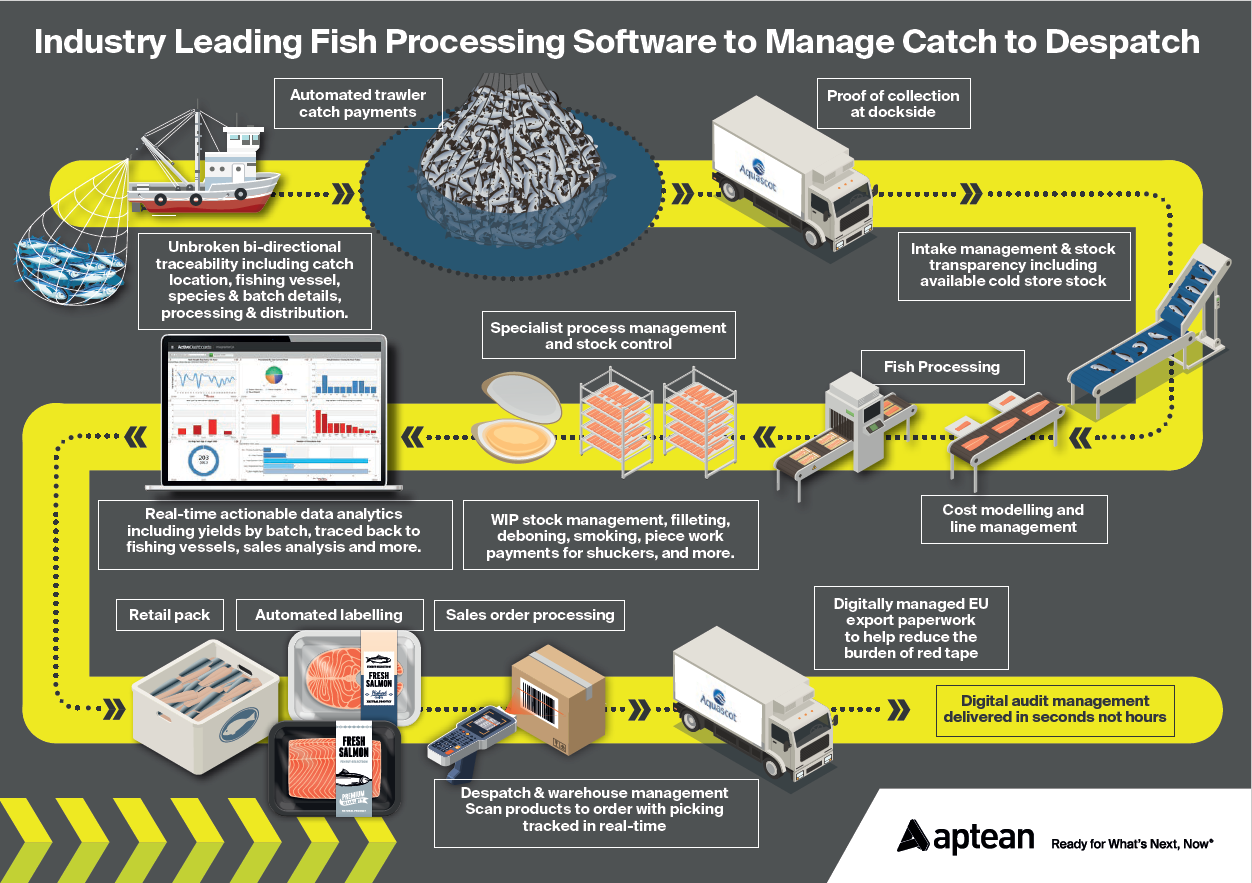

Cost Modelling and Line Management

With SI Cost Modelling and Line Management Set up calculations for the entire value of the fish against the production output, such as the price of a whole salmon against its filleted output and the product codes.

Fish market rate prices are subject to extreme volatility and can change by £1-2 per kg each day. SI’s cost modelling software takes account of the current price for landed fish by species, fish processing stages, and calculates the price for finished products and retail pack.

Using our cost modelling software, calculations are set up for the entire value of the fish against the production output. For example, the price of a whole salmon against its filleted output and the individual product codes.

These detailed product codes measure the differences in yield and cut, including:

- Skin on (when the yield will be better)

- Skin off

- Square cut

- Trim

For specialist processes, such as smoked salmon, the trays of fillets are issued to a smoking process. Afterwards, the fillets are weighed and booked as a smoked product.

Managing product substitution

Another option available is within our cost modelling software is product substitution management, where the differences in yields and giveaway will be measured for fixed weight.

DOWNLOAD our Fish & Seafood Processing Infographic [si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]To find our more about fish processors are using SI’s cost modelling and line management software, simply complete the form and we’ll get right back to you.

-

Cost Modelling and Line Management

SI’s cost modelling software takes account of the current price for landed fish by species, fish processing stages, and calculates the price for finished products and retail pack. For example, the price of a whole salmon against its filleted output and the individual product codes.

-

Stun Monitor

Capture stun monitor data in real-time, every time. As each animal's stunned, SI’s abattoir stun monitor records and displays signal data, including details for duration and power of each stun, and measures against acceptable standards.

-

Recipe Management

Using SI's recipe management software, digitalise, visualise and control the creation of the most complex value-added products. ready meals and bakery recipes from component ingredients

-

Kill Line Tracker

The Kill Line Tracker provides a great visual about what’s happening daily within an abattoir, across the kill line and at each data capture point. It tracks what animals have been booked in, what’s going through the kill line and what’s left to do. For multi-site abattoirs, manage and track with central controls.

-

Shop-Floor Management Dashboards

Our data-driven dashboard tool provides real-time visibility to monitor and understand process-specific performance.

-

Abattoir Grading Station

Our easy-to-use abattoir grading station software profiles carcases types. weights, grades and ages. It collects weight details, and ensures consistent standards are applied. Use it to label stock according to varied species, carcass types, specifications and ages.

-

OCM and labelling

SI's OCMs and labelling software provides accurate multiple labelling options, essential for the success of all food processors, "delivering 100% consistency in labelling across all 15 production lines" Avara Foods.

-

Automated Livestock Payments

Our Livestock Payments application monitors all abattoir grading to calculate prices, taking account of adjustment averages, Eurogrid, & even agent commission. It works out market consignment profitability, and also checks farm assurance status via integrations with Red Tractor, SPECC & other schemes.

-

Yield and Giveaway Management

Reduce giveaway on fixed weight products, improve yield and achieve better scheduling.

-

Abattoir Traceability

Complete abattoir traceability delivered in minutes, not hours. Systems Integration’s abattoir traceability software, captures livestock data from bookings, scheduling, lairage and kill line to grading, carcase stock and delivery, delivering complete visibility of the slaughter process.

-

Materials requirements planning (MRP) software

Having the right stock available at all times is vital to the success of any food producer. Too much can lead to downgrades and waste, too little to shorting orders and unhappy customers. And within the food factory, efficient planning to ensure the most effective use of the supply network is crucial to maximise customer satisfaction. SI's MRP (Materials Requirements Planning)provides an effective and efficient solution.

SI's MRP (materials requirements planning) system - Stock and Order - takes a stock snapshot across all stocked product. Based on actual purchase orders and by using sales forecasts, BOM and yield conversions, it will display stock shortfalls and flag when product needs to be ordered. It also highlights when food manufacturers are holding too much stock or when stock is at risk of going out of date.

With SI Stock and Order, you can take a lean manufacturing approach to food production, ensuring cash is not tied into stock or paying for additional storage.

Our material requirements planning (MRP) system provides food manufacturers with a real-time view to manage raw materials, work in progress (WIP) and packaging, and for all product types.

By delivering forward reporting ahead of time SI's Stock and Order also supports better relationships with suppliers for re-ordering and insights into stock consumption by product. By highlighting trends for both fast and slow-moving product categories, it also supports better planning and sales opportunities.

The application will show product shortfalls and will indicate to the planner when more raw material needs to be moved from one location to another or ordered to fulfil stock demand taking in to account transit/supplier lead times.

The MRP system then enables planners to send draft POs to SI's Purchase Order Processing application for approval. And if Stock and Order highlights that too much raw material stock for a specific product code, this will also be highlighted, enabling food manufacturers to react ahead of time to rectify the issue – i.e. promotions can be set up in SOP.

With SI's Stock and Order, you can take a lean manufacturing approach to food production, ensuring cash is not tied into stock or paying for additional storage.

[si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]To find out more about SI’s "Stock and Order" MRP system, planning, food ERP and MES software, simply complete the form and we’ll get right back to you.

-

Carcase Stock Tracker software

DOWNLOAD OUR LATEST ABATTOIR & MEAT PROCESSING BROCHURE Need a way to track every carcase, side and primal in real-time within your abattoir and cold storage? SI's Carcase Stock Tracker application provides the solution.

With Carcase Stock Tracker, forwards and backwards traceability is guaranteed, thanks to unique batch ID labelling applied to every forequarter, hindquarter and flank.

For every cut made, SI's Carcase Stock Tracker Application:

- Uniquely records individual weights by carcase and for every primal.

- Controls all spec ID details and labelling credentials.

- Captures data for all separate pieces as they are booked.

- Identifies what’s left to sell.

- Recalculates the weight.

- Accounts for every action taken

- Delivers real-time chiller location visibility, pinpointing locations of all carcases or sides.

- Provides the stock balance and automatically rebooks the original product.

- Maintains exemplary traceability across chillers, including weights, ages and by specifications.

“Nothing is more complex, trace-wise, than accounting for everything that’s derived from a beef carcass when it’s butchered. At Farmison & Co, we label every individual primal. When you walk into our fridges, every single piece of meat – whether it’s packed, primal or exposed – has a full SI label on it.

"It’s best practice, but not common practice within the meat industry."

Michelle Kennedy, chief operations officer, Farmison & Co.To find our more about SI’s carcase stock tracker software and abattoir management s/w solutions, simply complete the form and we’ll get right back to you.

Finally, SI Food Software.

Also, SI Carcass Stock, carcase stock, carcase balance, carcass balance. -

Picking and Despatch

Our picking and despatch real-time web-based solution significantly reduces the opportunity for human error, ensuring what's ordered is delivered and dramatically cutting down credits.

-

Auto-spec ID

SI's Auto-Spec ID application analyses kill line data and determines how best to use every animal against specification criteria. The software shows the best fit against customer specification categories in seconds, allocating and prioritising by specification and price.

-

Proof of delivery

SI's Proof of Delivery application is proven to cut customer credits by up to 80%.

-

Boning hall intake software

DOWNLOAD our Abattoir and Meat Processing Brochure [si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]To find out more about SI's market leading boning hall software, simply complete the form and we’ll get right back to you.

-

Boning hall intake

SI's boning hall intake, together with our Carcass Stock Application, eliminates typical manual operators often occur when carcasses are issued that don't match production specifications. SI's boning hall intake screen precisely shows operators what needs to be produced, carcase type and batch specifications, including carcase spec IDs.

-

Cost Modelling

What margin will I make today? How much does it really cost to make my products? Our Cost Modelling software has the power to solve many of today's food manufacturing planning challenges. Automate calculations to achieve continuous and accurate data to help prevent overspend and unearth savings, wherever they can be made.

-

Boning Hall OCM

As boning hall products reach the end of the production line, our OCM software and scales (Outer Case Markers) capture all weights and produce labels for boxed primals.

-

Boning hall OCM software

As boning hall products reach the end of the production line, our OCM software and scales (Outer Case Markers) capture all weights and produce labels for boxed primals.

For some of our meat processing customers, we’ve also set up our boning hall OCMs to label bagged primals before products are packed into boxes, This means that when boxes are delivered at customer sites, operators only need to scan the box label to identify all the products. In this case, as the primals reach the end of the production line:

- Primals are wrapped in a bag;

- Each bag identified with a batch number label;

- Groups of bags are boxed and weighed on an OCM scale, against the precise production batch, tracing back to the original carcase.

- Trim and fat is also boxed up, separately weighed and booked out.

DOWNLOAD our Abattoir and Meat Processing Brochure [si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]To find our more about SI’s boning hall software and OCM hardware, simply complete the form and we’ll get right back to you.

Finally, SI Boning hall OCM

-

Reporting and Analysis

Reporting & analysis for the food processing industry.

-

Boning hall yield and trim management software

Based on the way the primal is expected to be cut, within our boning hall planning software, the relationship between forecasted and actual boning hall yields can be tracked.

All boning halls have yield applications, but few of these applications can reveal what trim has been created and compare against what should have been produced. Our boning hall yield and trim management software precisely shows what was produced, planned and what should have been produced.

With SI’s unique boning hall yield and trim software, boning hall managers can:

- Measure against the plan;

- Identify when problems are occurring, such as excessive trim generation;

- Calculate what trim will be produced by specification;

- Compare what was planned against the actual trim output.

- Review any deviations from the planned production in real-time.

DOWNLOAD our Abattoir and Meat Processing Brochure [si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]To find our more about SI’s boning hall software and how it could improve efficiencies within your meat processing plant, simply complete the form and we’ll get right back to you.

[vfb id=5]

-

Boning hall yield and trim management

Unlike most competitive systems, SI's boning hall yield and trim management software precisely reveals what trim was created, and compares it against what was planned and should have been produced.

Choose from our sector specific software

- Sector Specific Software

- Abattoir Software Categories

- Bakery & Cake Manufacturing Software

- Catering Butchers & Food Service Software

- Cheese & Dairy Management Software

- Fish & Seafood Software

- Fresh Produce Software

- Meat Processing Software

- Pet Food & Bird Seed Manufacturing Software

- Recipe and ingredients

- Snacks Manufacturing Software

- Software for Poultry Processing