Our Software.

-

Raw material intake management software

From managing boxes of primals, carcasses or factored goods, SI’s Raw Material Intake Management software is just one of the reasons why Integreater is the sector's #1 IT solution.

For food manufacturers, when it comes to managing raw material intake, every day presents complexity. If your intake processes are resource heavy and hampered by paper, we can help.

We know how time-consuming raw material intake is, especially when re-labelling is required. That’s why SI's dynamic and modular raw material intake software makes the most of digital controls and barcode technology.

Whether booking in meat carcasses, primals and mixed pallets, dry and wet ingredients, fresh produce or even factored goods – many food processors are reliant on paper-driven processes to control the sheer scale of this daily task. But if your workforce is tied up with inefficient and expensive manual intake checks, it’s inevitable that errors will escalate.

This is because at SI, we’ve applied our in-depth knowledge of this sector and specifically developed software that matches the challenges of this fast-moving catering industry, where traceability and customer service are key.

Our user-friendly technology:

- Tackles all basic stock intake

- Decodes supplier labels upon arrival

- Handles mixed pallet meat inventory and eliminates the need to re-label every box within it

- Automatically books carcasses and products into relevant raw material chillers with each scan

- Provides real-time visibility of your stock and full traceability.

Simplifying mixed pallet inventory management

Raw material intake is complex; every day presents the challenge of managing everything from carcasses, primals, mixed pallets and factored goods.

For mixed meat pallets, most software systems need each box to be re-labelled. This means that for a mixed pallet, each and every order quantities, sizes and kill date information will need to be recorded.

With SI, we’ve simplified mixed pallet inventory management, eliminated the need to re-label every box within your mixed pallets.

Our handheld scanner driven technology captures:

- Product descriptions and codes;

- Location details about where each animal was born and reared;

- Slaughter location and date;

- Cut in, use by dates, and weights.

And as each scan is made, book raw material into the relevant chillers. More than that, whenever an individual box barcode is scanned to production for issue, all information remains intact, including kill dates, age, weight, provenance and complete traceability.

Intake management for overhead track scales

Whenever hanging stock arrives at intake, we’ve also got that covered by using our own stainless-steel and configurable touchscreens, combined with scale indicators and printers.

As each carcass is weighed, and an individual label produced, it is booked into the chosen hanging location for stock, and all mandatory track and batch information is recorded. And whenever carcasses are either moved to a different location or issued for cutting, traceability will be maintained by scanning product in and out.

DOWNLOAD our Meat Processing and Abattoir Brochure [si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]To find our more about SI’s catering butcher and food service software, simply complete the form and we’ll get right back to you.

Finally, SI Food Software.

Also, SI Catering Butchers. -

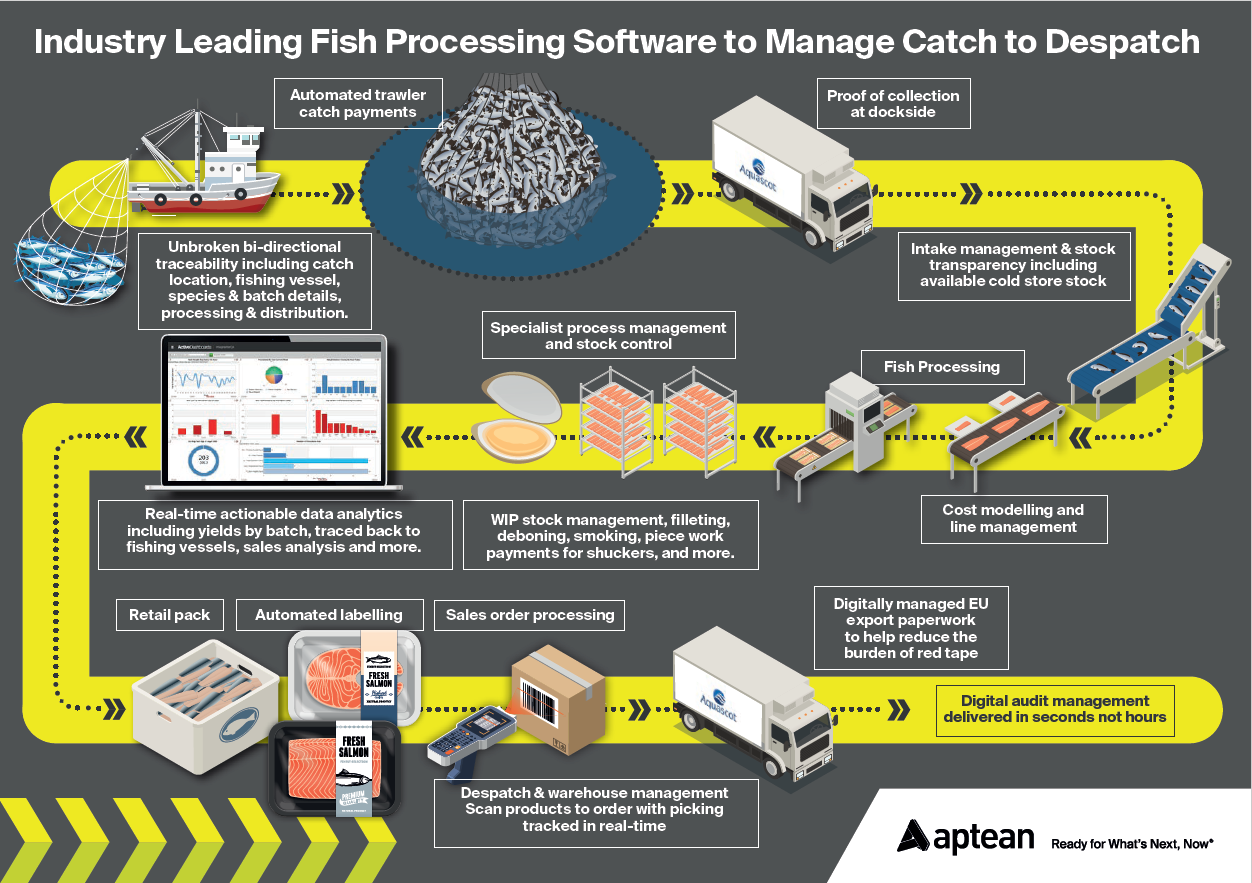

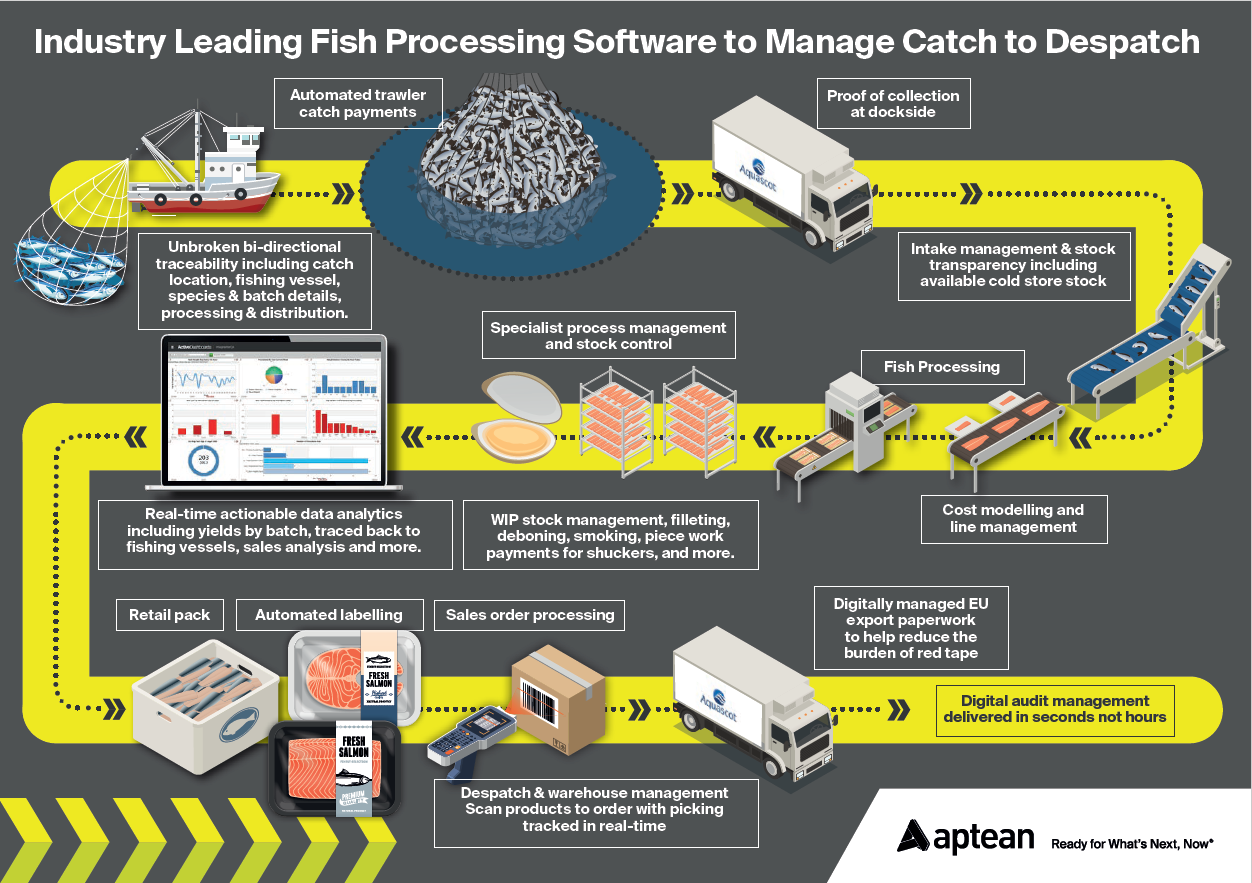

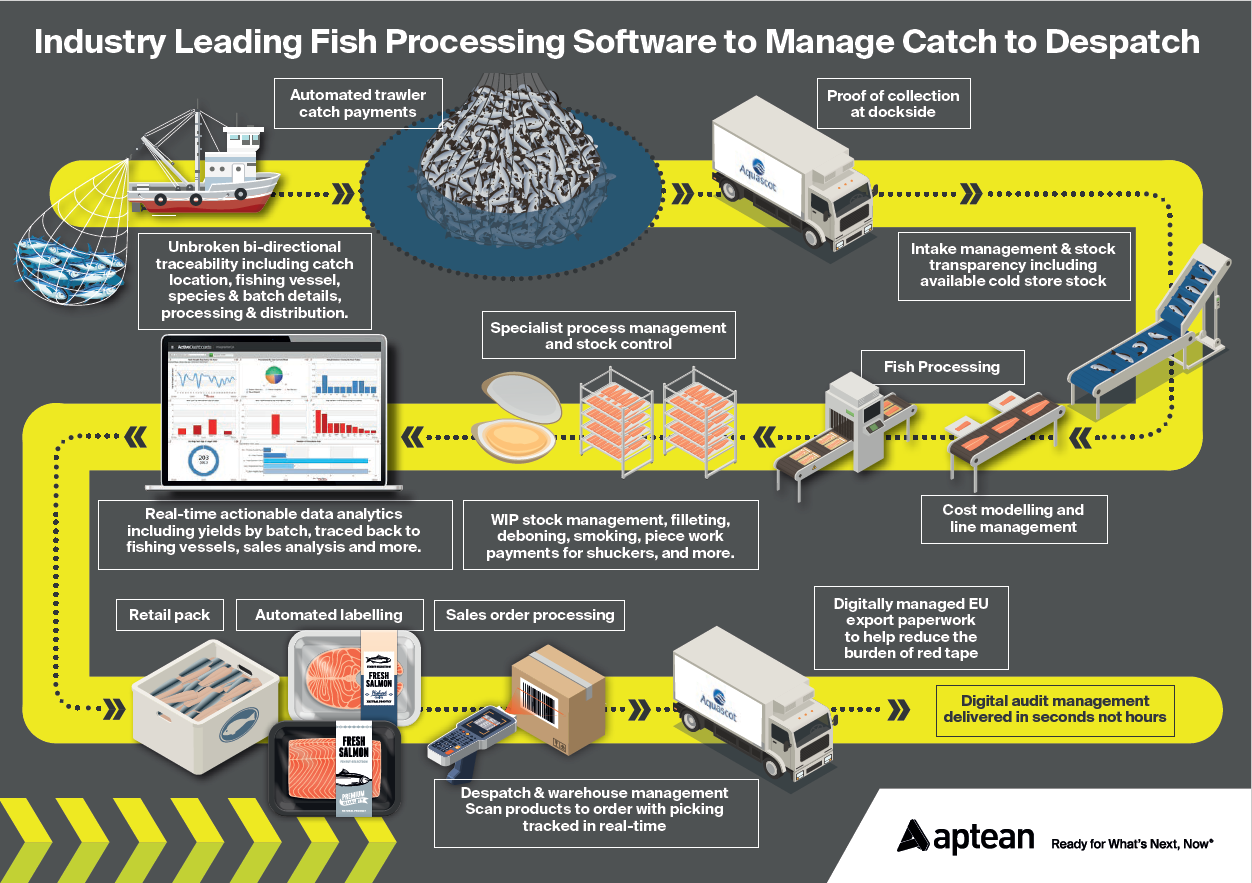

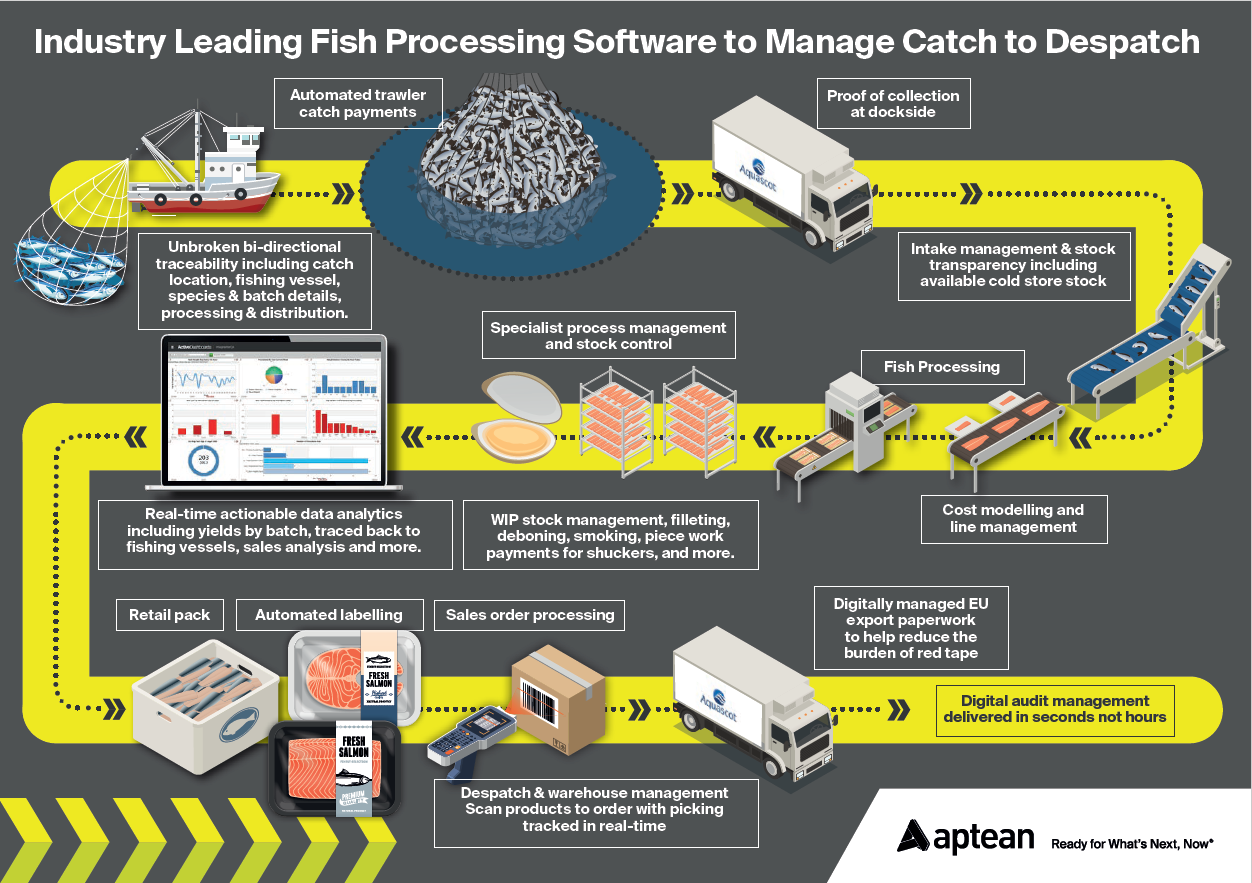

Trawler catch payments software

For fish processors that handles payment of Government fees on behalf of skippers, then charge fees back to them, SI's unique software to capture all this detail as part of the payments process with trawler catch payments.

“We have strong long-term relationships with skippers and fishing vessel operators and strive to ensure we help them any way we can. As a major part of our commitment to the Cornish fishing industry, we invested with SI to streamline our processing and payment systems.

“This way, the skippers can concentrate on landing their catch each day, whilst maximising the value achieved from every sailing.”

FalfishHandling payments bought directly from skippers

For many fish processors, their biggest payments challenge is whenever shipments are directly bought off the back of the boats and trawlers. Each container will comprise a mix of fish and seafood, ice and water. Of course, it’s impractical for the processor to check it. This would mean extra handling damaging the fish and the raw material needs to be processed within 24 hours.

SI has developed a clever solution to this dilemma, which we call “backflushing”. Whenever fish and seafood shipments are booked at intake and sorted, our OCMs are programmed to capture all the fine detail. Then, as soon as the processor is ready to generate the purchase order, we backflush the order accordingly to match the finished product.

Take, for example, sea bream:

- The sea bream is booked against the purchase order (PO).

- SI’s cost modelling software calculates that in order to produce 1kg of filleted sea bream, 3kg of fish's required.

- 3kg of sea bream is logged against the PO.

- In the meantime, an estimated invoice will be provided by the skippers for what’s been caught.

- Cost modelling reconstructs what fish should have come in compared to what’s been provided.

Then, the skipper’s estimated invoice is compared to the actual purchase order. Then, dependent on the yield, the payment is adjusted. If the yield is poorer than estimated, the skippers will receive a lower payment.SI Fish processor.

Read our latest article on how digitalisation of EU-export paperwork is helping to reduce the burden of red tape for one of SI's innovative fish processing customers.

DOWNLOAD our Fish & Seafood Processing Infographic [si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]To find out more about SI’s fish and seafood software and how it could improve efficiencies within your operations, simply complete the form and we’ll get right back to you.

-

Trawler Catch Payments

For a fish processor that handles payment of Government fees on behalf of skippers, then charge fees back to them, SI unique software captures all this detail as part of the payments process.

-

Cheese Make Sheet Software

Gain tighter control of cheese make sheet

You know what it takes to make great cheese, we know that keeping a detailed record of the process is essential. That’s why you can now throw away the paper and go digital thanks to our unique automated cheese make sheet.

SI's cheese make sheet software automatically picks up process points in real-time, including:

- Supplier and batch details for raw material

- The vat and conditions of make

- Volume of milk in the vat, its density and fat levels

- Temperatures, moisture, salt content and PH levels

- Rennet details.

- When cheese is scored, turned, cut and salted.

It provides you with all the information you need to compare each cheese make with the final grade and quality achieved.

By removing manual processes and data entry, we have eliminated human error and reduced the stress levels for our cheese makers, as they are assured that the make data is always digitally recorded by the SI system.

Multi award-winning Welsh cheese companyAutomate your cheese make process pickups

At a detail level, we’ve automated the process pick-ups within the software. For instance, the application takes the temperature straight from the dairy system. It no longer relys on someone manually reading from a dial and keying in the data; it records the temperature milk is heated to and the time before rennet is added; and it captures the elapsed time for heating before it’s moved on to the next stage of the process.

I believe that all UK cheese makers would benefit from our cheese make sheet software

Rob Stephens, CEO, Systems IntegrationAnd for those elements that still need to be keyed back in, we’ve built the steps into the cheese make sheet process to ensure that information is recorded in real-time rather than retrospectively.

[si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]To find our more about SI’s automated cheese make sheet software and how it could improve operational process controls, simply complete the form and we’ll get right back to you.

-

Purchase Order Processing

Efficiently create new purchase orders for raw materials, dry goods ingredients, packaging, services, non-stock items and consumables. Choose delivery timeslots, units of measure, and colour code based on delivery status.

-

Poultry Intake and Processing software

From kill, grading, processing, through to retail pack, our software captures all your production KPIs helping you to understand in real-time, key information including:

- kill grades

- yields and WIP

- finished product stock levels

SI’s shop-floor data capture software delivers real-time control for every stage of poultry processing

Our software excels at managing grades and helping to minimise whole bird substitution. For each batch of birds, it delivers visibility across the resulting grades from the batch. It captures detail to help your producers deliver better and more consistent grades; information can include live bird analysis, feed type, shed details and the living conditions.

Monitoring the poultry kill line

When live birds arrive at the poultry primary production site, our software is used to scan the intake of chickens and follow the kill, it records all the grades achieved from the batch. If the resulting grades are not as expected, suppliers can use this information to review feeding and other conditions at the farms.

Processing and portioning

At intake, SI’s overhead track scale and screen captures shop-floor data about grades as they are booked into stock, through touch screen controls. This allows producers to know if they have the correct levels of raw material to fulfil orders.

For whole chickens, the best carcasses are selected and issued for processing after evisceration. For portioning, birds will be issued to the first cut, an automated process, where they are halved and second cut. At this stage, the halved carcases will be cut to specification; for instance, quarters, thighs, drumsticks or breasts, with de-skinning and de-boning carried out on the line.

Monitoring the process for real-time intervention

SI software tracks all stock and the entire WIP process, monitoring yield and giveaway measurements throughout production. By integrating the whole production line, through shop-floor-data capture, giveaway can also be highlighted in real-time, using strategically positioned visual dashboards. This gives line managers the opportunity to alter the line, reducing giveaway.

Eliminating manual errors through automating the labelling process

With producers often supplying multiple customers, by automating the production line labelling volume products can be batched together, as once each order is complete the system will stop the line for relevant label changes.

With the labelling system automatically recognising the correct labels whenever a change takes place, there is no possibility for labelling errors. In addition, with all the relevant labelling information also sent automatically from the SI Hub both fixed and catch weights can be labelled accordingly.

Poultry for food service

In a similar way as our large catering butcher customer base, poultry food service is a high product proliferation business. That is, less volume and more variations. Finally, Our scan, pick and despatch applications ensure every customer's order matches individual sales orders. Our outer case labels applied to the box, confirm the transaction.

Finally, Si Food Software.

DOWNLOAD our Poultry Processing Brochure -

Poultry Intake and Processing

From kill, grading, processing, through to retail pack, our software captures all your production KPIs helping you to understand in real-time, key information including: Our software excels at managing grades and helping to minimise whole bird substitution. For each batch of birds, it delivers visibility across the resulting grades from the batch.

-

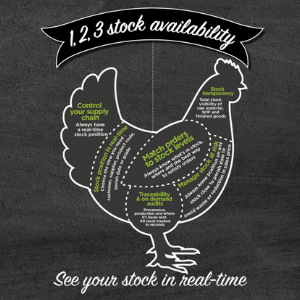

Real-Time Poultry Stock Management software

Join up your poultry stock with one real-time version of the truth

At SI, we see stock control for poultry processors and wholesalers as a four-step process:

- Raw material. Procurement, intake and stock control all managed in real-time.

- Work in progress. With complete visibility across production, know what stock is available to make finished goods. Know what your WIP position is and, when orders change, the adjustments to make.

- Finished goods. Be in control to meet demand. Know your availability of whole birds and portioned products as finished goods.

- Prevent stock going out of date, shorting orders, or even being destroyed.

Using our knowledge of poultry processing gained from working with some of the UK's largest producers, from intake to finished product, we’ve adapted our MRP stock control software to meet your daily challenges. Our software can provide you with

- Transparency across your business operations.

- Sales orders or sales forecasts.

- Stock control.

- The actual requirement for raw material stock that’s needed to fulfil customer orders.Our real-time view will:

- Cut out paperwork errors and save time.

- Improve management of procurement, intake and stock control.

- Show whatever is in stock, where and the best way to satisfy orders.

- Provide stock transparency across raw material, WIP and finished goods.

- Highlight and manage stock at risk.

- Enable joined-up traceability, with stock tracked in seconds, to ensure you are always audit ready.

Combining this information with our easy sales analysis reporting, you’re able to see the detail on products that are selling. You'll know who’s buying, and for what price. In real-time, our system highlights any raw materials in danger of running out and whenever stock needs to be reordered.

By working with SI, your poultry processing business will always understand your exact stock position. It will know what products are at risk of going off, and how you can cut down on waste.

[si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]

DOWNLOAD our Poultry Processing Brochure -

Real-Time Poultry Stock Management

SI works with some of the UK's largest poultry processing companies. Our controls ensure that they always have a real-time understanding of their stock position, from raw material intake through to finished goods. Always know what products are at risk of going off, and how you can cut down on waste.

-

Least Cost Formulation

Optimise your recipe-based products with SI's Least Cost Formulation. Within our Cost Modelling solution, Least Cost Formulation steps up planning controls by taking account of specification variances of available raw materials (E.g. VL grade), whilst still delivering at least cost.

-

Butchery screen

SI’s Butchery Screen is the most efficient way for Catering Butchers to manage customer demand and fulfil orders. Our screen displays the plan, allows butchers to view giveaway, throughput and yield in real-time.

-

Catering Butcher touchscreen software

SI’s Catering Butcher screen is just one of the reasons why we're the #1 software solution for the sector.

Our touchscreen driven application bridges the gap between sales orders, production planning and what happens on the shop floor, whilst showing how best to cope with constantly changing demand.

By using our catering butcher screens, master butchers and planners are confident that every customer order, whether trade or B2C, is fulfilled to match the latest specifications.

Not only do our screens can also show real-time giveaway, throughput and yield.

Technology that empowers your master butchers

From Michelin-starrred restaurants to pub groups, with SI's unique catering butcher screen, be confident that every order is fulfilled to specification.

- Plan whatever needs to be produced and generate production runs;

- Then, using the catering butcher screen, produce products by sales order;

- And, scan primals and cut for optimum use;

- Also view product and preparation specifications;

- Receive real-time alerts, whenever orders change;

- Select specific cutting requirements by sales order;

- then, produce to stock;

In our partnership with SI, we’re investing in a technology platform that will future-proof our business.

Liam Duggan, finance manager, Farmison & Co

DOWNLOAD Baird Foods Customer success story [si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]For more information on our catering butchery touchscreen, or our work as the #1 supplier of food software to UK catering butchers, simply complete the form and we’ll get right back to you.

-

Catering butchers production management

For catering butchers, nothing stays the same for long, with short notice order amendments the norm. SI's planning, food ERP and software dramatically improves processes and efficiencies. Once orders have been placed, our software converts to product codes to show production precisely what needs to be cut and produced.

-

Catering butchers production management software

Adjust your production in real-time with butchery management software

For catering butchers, nothing stays the same for long, with short notice order amendments the norm. As we know from visiting customer sites, adverse shop-floor issues, unless they are dealt with quickly, will have a negative impact on margins; the ability to adjust production in real-time is essential.

With SI's food production planning and ERP solution, whenever adjustments to production are made, this same information automatically updates the sales orders. Then, once orders have been placed, our software convert them by product code, showing your catering butchers exactly what needs to be produced, including what need to be drawn down from stock to fulfil orders and how it should be cut.

And as all weight-related data is captured, including carcass intake, primal booking and residual products out, real-time reporting is always available about boning yield and mass balance.

DOWNLOAD our Catering Butchers Infographic here [si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]To find our more about SI’s catering butcher and food service software, simply complete the form and we’ll get right back to you.

-

Boning hall cut-tree cost modelling-software

Maximising carcase balance is the greatest challenge within the meat processing industry. SI's cut-tree cost modelling delivers a joined up view of kill, bone and retail pack.

It accounts for all boning hall cut specifications and delivers a detailed understanding of carcase profitability, by planning out product relationships for how carcases and primals should be cut and split down.

Using SI's Cut-Tree cost modelling, with a joined-up view of kill, bone and retail pack, boning hall planners can find the best way to:

- Make data-driven, informed decisions rather than relying on gut instinct (albeit very skilled gut instinct). Understand the implications of boning hall decisions before they are acted upon;

- Detail the best and worst margins for each product;

- Bone out all carcases to make the most money;

- As the Cut-Tree informs the kill plan, find a home for all meat, not just the premium products;

- Manage the push v pull, and improve understanding of demand;

- Mimic any process and compare with what happens within the boning hall.

Making the best use of trim

As understanding the level of meat trim that will be generated within the boning hall is critical, to enable decisions to be made well within its shelf-life, our Cut-Tree cost modelling software does the hard work and works out the fine detail of trim predictions.

Whether it's 80, 90 or 95VL, our cost-modelling software will help you find the best way to use every trim product.

DOWNLOAD our Abattoir and Meat Processing Brochure To find our more about SI’s boning hall software and Cut-Tree cost modelling, simply complete the form and we’ll get right back to you.

-

Boning hall cut-tree cost modelling

For boning hall managers and planners, our cost modelling software, also known as the SI Cut-Tree, delivers a detailed understanding of carcase profitability and the implications of boning hall decisions before they are acted upon. With a joined-up view of kill, bone and retail pack, decide the best ways to cut and split down carcases and sides.

-

Meat processing sales and forecasts

Vertically integrated large meat processors will know how many carcasses are likely to be coming through each day and the different profiles. The problem they face is how best to fulfil customer orders against the available raw material and optimise the sales margins. SI's Available to Sell software projects raw material stock availability to fulfil orders and also provide a real-time view. It targets the sales teams to sell the in-balance and sell higher margin products. With Available to Sell:

- Start with new opening stock every day.

- Know when products will be available to sell.

- Have the detail to look for orders for all products, even for the ones that need to be matured for two weeks or more.

- Highlight unsold products, that are about to go out of date and need actioning.

-

Intake and stock management-software

For fish and seafood processors - unlike other sectors of the food processing industry, where raw material can be weighed to validate whether the weights supplied are correct - weighing boxes at intake will not provide a meaningful measurement.

Aside from fish and seafood, every box contains a high percentage of ice and water, therefore the processor has to rely on the pallet weight provided by the supplier.

Fish stock management

Once the daily catches are sorted into different species and booked into stock, SI’s sales order processing (SOP) module matches orders to the fresh stock intake and available cold store stock to provide:

- A quick and accurate view of stock availability.

- Highlight whether there is too much stock of one species and not enough of another to fulfil orders.

- A view, by product code, of any other seafood caught in the batch.

With real-time information, real-time decisions can be made to determine whether to source more stock, change plans to put excess fish stock into cold storage or alert sales to contact potential customers.

Supporting sustainability of the fishing fleet

Our software not only simplifies matters for the fish processor, but also for the skippers. If the processor is categorising the catch, our software also captures the shelf life. With clear visibility of stock, real-time decisions can be made for anything not part of a production run.

For instance:

- Seafood - such as octopus, can be quickly sold on rather than having to downgrade or written off as waste.

- Exotic fish can be sold to supermarkets as part of a fish box. Then to be sold on directly on the fish counter in stores.

Read our latest article on how digitalisation of EU-export paperwork is helping to reduce the burden of red tape for one of SI's innovative fish processing customers.

DOWNLOAD our Fish & Seafood Processing Infographic [si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]To find out more about SI’s fish and seafood software and how it could improve efficiencies within your operations, simply complete the form and we’ll get right back to you.

-

Intake and Stock Management

At intake our software records all traceability information, including species and catch details, and generates the puchase order. Then, with SI's stock management controls, fish processors can determine whether to source more stock, change plans to put excess stock into cold storage or alert sales to contact potential customers.

-

Cheese Grading Software

SI's cheese grading software has revolutionised the way that maturation data is captured and managed. How? By providing skilled cheese graders with instant access to batch or product information, driven by real-times data capture, no matter where they are located.

SI's cheese grading software updates entire batches in real-time, whenever blocks are graded. The software even reminds you whenever blocks are next due for re-grading and produces grading schedules. And, by using mobile devices, it's quick and easy to record cheese grading information.

With a live view of every block of cheese in stock, cheese makers have all the data they need to select the right blocks at the right time to maximise their revenue.

SI's cheese grading application provides a real-time view of every block of cheese, its grade and where it’s located, ensuring older stock isn't forgotten. And to ensure that your customers have the right products, it also automatically identifies the best products for them, based on the cheese profile.

Request and download our cheese brochure to find out more about our unique cheese grading software.

The software is also capable of tracking issues with cheese, such as green spot. By checking historical data and the make data, cheesemakers can analyse these factors. This analysis will help to determine what’s causing sub-standard cheeses, versus the higher quality cheeses that have the potential to deliver the highest revenue.

We’ve also simplified reporting, with either auto-generated on demand reports. Just select who should receive each report, when, how often and define the required information. For example:

- Which cheeses are due for inspection within the next seven days?

- Are there any overdue blocks?

- When will be the best time to cut, pack, and despatch the cheese?

Always know how your stock is maturing

Of course, the value of cheese depends on the grade it achieves. It's the reason why batches have to be regularly tested.

With our cheese grading application you'll always have a real-time stock view, no matter where your batches are kept, block ages and however many times regrading has been performed,

The application eliminates operator errors by gating options by cheese product. For example, the available choices for a cheddar would be restricted to grade, sub-grade and age. And, whenever operators need to access information, such as starter culture, it can be retrieved within seconds.

[si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]To find our more about SI’s cheese grading software and how it could improve your cheese make processes, simply complete the form and we’ll get right back to you.

-

Kill Scheduling

Create profiles, break kill quantity down by percentages and specs with SI's abattoir kill scheduling module. Create weekly schedules, based on daily profiles, organise booking/sequential time slots. View lot numbers, animal quantities, supplier/producer codes and more.

-

Production Planning

SI's food production planning provides a real-time view of scheduling, dynamic planning and allows you to make last minute changes, no matter when they happen during the day. Identify live issues and calculate the knock-on effects to production time and lines, raw materials, crew, packaging requirements and even vehicle departure times.

-

Sales Order Processing Software

Our highly configurable Sales Order Processing software has been developed to meet the operational requirements of any food manufacturing business. Features include customer templates, shopping baskets, historical sales by customer, promotions, multiple price lists, 3-tier pricing, draft orders, full audit trail, credit limits, CRM, rebates, reporting on demand, and much more

-

Sales Order Processing CRM

Create call lists for telesales team members, or even a call list for a telesales group, with our SI’s CRM module.

-

Poultry Processing Planning

Using SI's planning software suite, producers can step up to a new level in planning automation and decision-making. Understand how many chickens need to be killed, how many whole bird carcasses will be delivered and how many need to be portioned, minimise shortfalls, surpluses, giveaway and whole bird substitution.

-

Poultry Processing Planning Software

Through the combination of our Plan to Produce and Available to Sell software modules, producers can move up another level in planning automation.

Using this software from SI, you can work out against predicted orders:

- How many chickens need to be killed

- How many whole bird carcasses will be delivered and how much needs to be portioned

- Minimising shortfalls or surpluses

- If there are likely surpluses that need to be planned for sales promotion

- How to minimise giveaway and whole bird substitution

Planning and available to sell reduces cold storage

With orders often varying due to promotions or changes in demand, planning and knowing what is available to sell is critical to achieving the best margins for a whole processed bird. Having high breast sales but low wing sales, producers have the choice of buying in breasts at higher prices or processing more and finding a market for wings.

With freezing product requiring additional cold storage investment and leading to a reduction in saleable value by 30% or more, compared to fresh, understanding stock volumes and what is available to sell can make a big difference.

Automating impacts of carcass contamination

Finding birds with any carcass contamination, impacts of not being able to use the raw material cause planning issues. This is the reason why the SI system can automate stock volumes. To provide your production team with real-time information on available raw material. Also, what impact any detected issues will have on achieving the golden rule of fulfilling customer orders.

DOWNLOAD our Poultry Processing Brochure -

Production Tracker

Validate raw material, reduce wastage and deliver real-time information about whatever's happening within your food factory by using SI's Production Tracker screen.

-

Stock and Order

Reacting to changes in customer orders, whilst ensuring the right stock is in place can be a complex and challenging task. Our real-time stock and order management solution combines all data from forecasts to on-the-day customer orders and stock positions, using BOM information (from cost modelling), stock information across all locations, sales orders and forecasts to provide a live view of future stock positions. Streamline food manufacturing decision making to achieve more profitability.

-

Boning Hall Planning Software

Whenever an animal has been killed at the abattoir, swift decisions must be made about what should be done with the carcass or hanging sides.

- Will your meat processing business achieve better margins by selling the primals?

- Would it be better to use primals within your retail pack operation?

Planning what to produce and fit with what's sold

Every meat processing company is faced with having to plan for kill and boning before having a complete picture of what will sell. Whether it’s beef, pork or lamb, making the best meat boning hall planning decisions means the difference between profit and loss.

When it comes to boning hall planning, many meat processors rely on paper processing and tacit knowledge. Decision making is reliant on "islands of efficiencies, such as different departments, plans and multiple spreadsheets.

The result? Planning is very reactive, according to whatever has happened during the day.

- What am I going to sell and what do I want to sell?

- What’s going for a better price this week?

- Which products to produce this week, that can be sold for a better return?

But within the boning plant, deciding what needs to be produced and ensuring that these product match up to whatever's required, can be quite a different story.

Introducing Plan to Produce

Using SI's Plan to Produce software, meat processors can plan out boning hall requirements based on primal and retail pack demand. Then, review progress against the plan, assess operational and operator performance - all in real-time.

Plan to Produce is effectively a visualisation of cause and effect. It will show when there’s not enough product coming through, and if it doesn’t match, boning plan can then be changed to match what you are selling.

DOWNLOAD our Abattoir & Meat Processing Brochure [si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]To find our more about SI’s Plan to Produce and boning hall software, simply complete the form and we’ll get right back to you.

Finally, SI Food Software.

Also, SI Catering Butchers. -

Fish Processing Software

Real-time insights from batch issue to retail pack

Our OCMs manage more than just labels. They're also managing the calculations, based on the yield, ensuring that batches are correctly changed. Whether you need to track by delivery or relatively small batches, OCMs monitor batches, preventing automatic overbooking and booking against incorrect production runs.

If a better yield has been achieved, a manual override can be made and recorded. With these checks and balances in place, booking to

production will always be done right the first time, for auditing, traceability data will be robust and accurate.

If operators attempt to book more than the expected yield, this can only be achieved by a manual override of the system. These built-in checks are designed to ensure:

- Production plans are followed.

- Operators change batches at the right time.

- Next batches aren’t accidentally booked to the run.

Read our latest article on how digitalisation of EU-export paperwork is helping to reduce the burden of red tape for one of SI's innovative fish processing customers.

Controlling production of specialist processes

For specialist processes, such as smoked salmon, the trays of fillets are issued to the smoking process. Afterwards, the fillets are weighed and booked as a smoked product. Again, our cost modelling features a different yield for these smoked products due to weight reduction. Click here to find out more about our unique cost modelling and yield management for fish and seafood processors.

At this point, our software is keeping track of the balance for what’s been issued (using a trace ID) and the resulting weight after production, and after it’s been packed and sealed. If the weight exceeds the expected amount then production is halted.

DOWNLOAD our Fish & Seafood Processing Infographic [si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]To find our more about SI’s fish processing software and how it could improve efficiencies within your fish factory, simply complete the form and we’ll get right back to you.

-

Fish Processing

With SI's fish processing software and OCMs, manage yield calculations, ensure batches are correctly changed, monitor batches, prevent automatic overbooking or booking against incorrect production runs.

-

Veterinary Data Management

SI's veterinary data application and screen digitalises all vet data, providing complete proof that an abattoir's adhered to all processes and legislation. By recording vet data on the kill line, it captures the many checks that prove an animal's health before slaughter, tracking data against each farmer/lot.

-

Cheese Stock Control Software

When you have control of your stock, you have control of your business. But for cheesemakers, when maturation constantly changes the stock profile, understanding stock value and controlling its availability is complex.

Track your cheese – from the minute it’s made with cheese stock control

With SI, it's easy. Our cheese stock control software delivers:

- A real-time stock view, showing precisely wherever maturing cheese it’s kept, as it moves around the store area;

- Records all blocks as they are moved into storage. after the cheese make process, and throughout the maturation cycle;

- Tracks where your test block is in relation to your stored pallet;

- Identifies, through individual cheese profiles which products are most suitable for your customers;

- Enables quick and easy access to the value of stock as it is graded, by identifying any variances, stock anomalies and rejections against the standard cost.

“As blocks are weighed and put into boxes, the SI system produces and applies barcode labels, with date codes and weights, and each pallet load of blocks is then logged into our storage facility.

"Using SI’s stock management software, we can automatically pinpoint wherever the cheese is located. With this level of automation, we can pick out cheese blocks later for retail pack processing or individual block despatch, to our manufacturing customers."

Award-winning UK cheese makerRegrade and automatically update product codes

SI' s real-time data capture provides complete visibility and traceability, eliminating manual and paper-based recording errors.

Whenever changes need to be applied to all cheeses within a batch, including regrading information, SI's Integreater stock software automatically changes all product codes and maintains historical data, and authorised staff can also add and record any useful information

Click on the link to find out more about our cheese grading software.

Download a copy of our cheese infographic and see how SI real-time data capture will enhance your cheese stock control and grading processes.

[si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]To find our more about SI’s cheese make and processing software, or request a brochure, simply complete the form and we’ll get right back to you.

Finally, Si Food Software and food ERP.

-

Software for Raw Material Intake

Simplify and speed up your raw material intake process with our highly configurable, modular application for food processors, driven by touchscreens and barcode scanners. Assign batch numbers and stock, and make the most of barcode technology and built in QA and traceability.

-

Yield Tracker

No matter what product you are processing, from meat to potatoes, the ability to track yield in real-time will deliver significant business benefits.

-

Stock Tracker

Always make the best use of stock across your enterprise with SI's stock management applications and reporting. Whether raw material, dry goods, packaging or WIP, track life left on products and enable better operational decision making with our live view of stock. Stock Tracker delivers a complete overview of business stock or by individual location. By product code, view by life or by age (for stock in maturation), generate reports showing stock valuation, stock by life, stock at risk, and much more.

-

Available to Sell

For food processors, constantly changing customer demand means that no two days present the same production requirement. With SI's Available to Sell real-time view of stock, based on raw material and orders received, updates in real-time The moment your production plan changes or a new order is received,

-

Livestock Ordering Point & Sampling Station

As part of our kill line solution, Livestock Ordering Point ensures animals are moved to the slaughter process in the correct order and creates a unique kill number for traceability throughout abattoir processing.

-

Fish Retail Packing Software

From batch issue to retail pack

With SI, whenever a batch of fish is issued for retail pack processing, it's booked against a production run that matches the planned products with a unique batch code. The batch code data:

- includes vessel identification, the catch date, and fish quota details.

- accompanies produces throughout processing, together with individual species barcode information.

- and informs label generation, whenever the product is packed and dispatched or put into cold storage.

Monitoring yield and tracking the batch

Our Outer Case Markers (OCM and labelling) manage more than just labels and booking to the production run. They also manage the calculations, based on the yield, and ensure that batches are correctly changed.

Whether you need to track by delivery or relatively small batches, OCMs monitor every batch to:

- prevent automatic overbooking or booking against incorrect production runs;

- ensure product output is booked only if it is correct.

Fish processors can also book trays of mixed fillets as work in progress (WIP), capturing the actual fillet weights rather than the supplier weight.

Note: In the case of a better yield being achieved, a manual override can be made and recorded.

Read our latest article on how digitalisation of EU-export paperwork is helping to reduce the burden of red tape for one of SI's innovative fish processing customers.

DOWNLOAD our Fish & Seafood Infographic [si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]To find out more about SI’s fish and seafood software and how it could improve efficiencies within your operations, simply complete the form and we’ll get right back to you.

-

Cheese Traceability Software

For cheesemakers across the UK, being audit ready has never been more important.

By working with SI and digitising cheese make and cheese grading processes, your audit data will always be up to date. With SI's real-time data capture and controls, your next food audit traceability check can be completed in seconds, not hours. You will have the level of transparency and traceability to meet the exact standards required from supermarkets and other suppliers.

Our cheese traceability software, not only ensures complete visibility and forwards and backwards traceability, but it also minimises recording errors that are typical when there's a reliance manual records.

Find out more about how to take advantage of SI's digital forwards and backwards traceability digitalisation to support your audit reporting and real-time decision making.

SI's cheese traceability software is clever enough to:

- detail different milk types;

- record how long the products have been stored for;

- distinguish when your products are vegetarian cheeses.

Whenever changes need to be applied to all products within a batch, for instance, re-grading from mild to medium, Integreater® automatically changes all the product codes within the batch, whilst maintaining all the original batch data.

DOWNLOAD our Cheese Manufacturing Brochure [si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]To find out more about SI’s cheese traceability software and how it could improve efficiencies within your dairy operations, simply complete the form and we’ll get right back to you.

-

Bespoke Cutting and Order Management

For catering butchers, when 1000s of orders are reliant on manual and paper-based control, it's inevitable that costly mistakes are made by operators. As the No.1 software supplier to the UK catering butcher sector, SI's unique catering butchery touchscreen station delivers real-time digitised bespoke cutting and order management information direct to your skilled butchers.

-

Bespoke Cutting and Order Management software

For catering butchers, within their highly varied customer orders, high product proliferation and bespoke cutting are daily challenges that must be met. When 1000s of orders are reliant on manual and paper-based control, it's inevitable that costly mistakes are made by operators.

As the No.1 software supplier to the UK catering butcher sector, our unique catering butcher touchscreen station* delivers real-time digitised order data direct to your butchers.

DOWNLOAD our Catering Butchers Infographic here With SI's touchscreens positioned directly at butcher stations:

- Select the daily plan detailing products to be cut.

- Based on orders received, converted by product codes, break plan down by each butcher on the cutting line.

- Instructions show every order to be produced, together with product specifications and cutting sheets;

- Scan meat and issue to relevant butchers.

- Weigh and label products, at either case level or after cutting at product level.

- Track product giveaway, run reports on yield, mass balance and even the speed of each butcher.

*SI’s mobile butchery station comprises our own stainless-steel touchscreen and printer.

DOWNLOAD our Baird Foods Customer Success story [si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]Does your business operates within this challenging sector? Would you like to discuss how SI, the No.1 software supplier to the UK catering butcher sector, can help you improve efficiencies with our food planning and production software, simply complete the form and we’ll get right back to you.

-

Fish and seafood labelling software

From catch to the consumer, commercial designation to production method - SI labelling software can match the challenges that fish and seafood processors face.

With strict legislation governing the fish and seafood sector, fish and seafood processors must evidence that everything that's been done in the legitimate way. And for labelling, the level of required detail includes whether catch was line-caught, trawled, fish-farmed and catch area.

With SI's fish and seafood processing labelling software:

- centrally manage and push out data digitally to drive OCM labelling.

- automatically configure data for the outer case as the product progresses down the line

- eliminate manual operator errors, as the software details are always correct.

- verify that all label barcodes are scannable

- through integration with third-party vision systems, provide extra labelling validation with photographic evidence.

Retail pack labelling validation

How it works:

- As part of planned production, when the raw material is ready for processing, the fish or seafood will be issued to said run.

- Whenever raw material arrives at the OCM, it's booked against this production run.

- To help operatives to always get it right, our software tracks production runs. Ensuring that the output doesn’t exceed what’s expected from the run.

- Our OCMs only allow operators to book output if it’s correct.

DOWNLOAD our Fish & Seafood Processing Infographic [si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]From catch to consumer, commercial designation to proceessing method, to find out more about SI’s fish and seafood labelling software, simply complete the form and we’ll get right back to you.

-

Fish and seafood labelling

From catch to the consumer, commercial designation to production method - SI's fish and seafood processing labelling software eliminates operator errors and verifies label content. Finally, SI Food Software. Also, Fish and Seafood.

-

Recipe management for wholesale butchers

With SI's recipe management software catering butchers will have full control of recipe masterworks orders, traceability, stock, WIP blends and mixtures.

-

Recipe management for wholesale butchers software

SI's Recipe Management software steps up digital controls across butcher recipe and added-value production, by providing centralised management of recipe masterworks orders, traceability, stock, WIP blends and mixtures.

How SI's recipe management software improves controls for catering butchers:

- Hold masterworks orders for all recipes and instructions for operators to follow as they weigh out each ingredient.

- As each ingredient is scanned in, maintain full traceability for each blend.

- Generate labels, once every component is complete, for the WIP bin.

- Have complete stock and ingredient visibility.

- Have complete ingredient traceability.

DOWNLOAD our Catering Butchers Infographic here [si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]Does your business operate within the challenging catering butcher and food service sector? Would you like to find out how the UK's No.1 software supplier to the sector can help your business? Simply fill in the form and we'll get right back to you.

-

Cheese Processing Software

Whether your a cheesemaker with a retail pack operation or a processor buying cheeses for cut packing, you need to understand how to achieve maximum yields from each cheese batch, together with the amount of secondary offcuts and waste resulting from each run.

SI’s cheese yield software captures details throughout the production batch run. From the time prime product is booked out, all waste, offcuts and mass balance is recorded; as an example, all waste generated from slicing or grating. It even details yield by supplier and different values of various cheeses.

Download our cheese make & cheese processing infographic to find out how SI's digitalisation could improve processes in your cheese business.

[si_button title="Contact us" url="https://sifoodsoftware.com/contact/" alignicon="right" color="green"]To find our more about SI’s cheese make and processing software, and how it could improve efficiencies within your operations, simply complete the form and we’ll get right back to you.

-

Pet food manufacturing dashboards and reporting software

Dashboards and data-rich reporting

Because SI’s technicians only work in the food production sector, we have a vast knowledge of how to integrate equipment on the shop-floor, enabling our customers to benefit from capturing data at every key part of the process.

With all data managed and processed in real-time by the SI central hub, we can create visual dashboards that give production teams within the pet food processing industry ‘one version of the truth’. One version of the truth will deliver complete visibility, QA control and traceability throughout your factory floor and back-office operations.

All pet food manufacturing processes can be checked, measured and reported on, including:

- Managing raw material checks at intake

- Ensuring processing machinery is operating properly (i.e. cooking, mixing and packaging)

- Confirming the right raw material has been added to the batch

- Capturing and managing specification tolerances

- Recording the actual conditions that the batch was subjected to for traceability.

- Producing the right date for canning or other OCM, labelling and packaging.

- Providing a failsafe picking and despatch solution.

-

Pet food manufacturing dashboards and reporting

With all data managed and processed in real-time by the SI central hub, we can create visual dashboards that give production teams within the pet food processing industry ‘one version of the truth’. One version of the truth will deliver complete visibility, QA control and traceability throughout your factory floor and back-office operations.

-

Production Forecasting

SI’s Food Production Forecasting module systematically predicts demand based on real-time data, and continuously adjusts the prediction ensure the most accurate forecasting. It delivers insights and visibility by combining information from sales teams forecasts, customer forecasts, stock levels and actual orders.

Choose from our sector specific software

- Sector Specific Software

- Abattoir Software Categories

- Bakery & Cake Manufacturing Software

- Catering Butchers & Food Service Software

- Cheese & Dairy Management Software

- Fish & Seafood Software

- Fresh Produce Software

- Meat Processing Software

- Pet Food & Bird Seed Manufacturing Software

- Recipe and ingredients

- Snacks Manufacturing Software

- Software for Poultry Processing